Haul-Off Belts Rubber

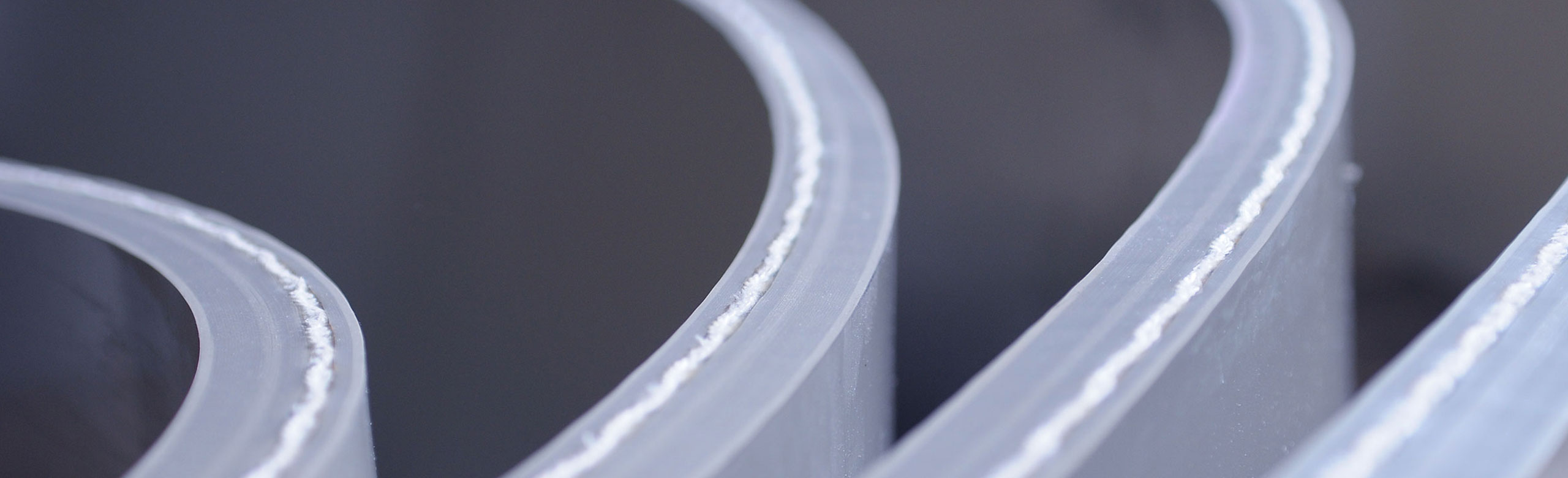

Strong tensile and contact forces, high speeds, and enormous heat development make our product indispensable for your machinery. Our seamless belts combined with our customised coating methods provide increased durability and a longer lifecycle, optimising your production processes.

Special haul-off belts for caterpillar machines, which are commonly used in the cable, wire, tube, moulding and plastic-extrusion industries, are our speciality. Here, our haul-off belts ensure smooth transportation of the haul-off material.

Scope of application:

Haul off of cables, tubes, wires, ropes and profiles.

Fabric:

Customised selection of the type of fabric and quality. All fabrics are produced endless and connectionless using a special manufacturing process.

Type of fabric: Polyester

Quality SPR 1500 (tensile loading up to 1.500 N/cm belt-width)

Quality SPR 2500 (tensile loading up to 2.500 N/cm belt-width)

Quality SPR 3500 (tensile loading up to 3.500 N/cm belt-width)

Type of fabric: Aramid (Kevlar©)

Quality SPR 4000 (tensile loading up to 4.000 N/cm belt-width)

Type of fabric: Steel

Quality SPR 5500 (tensile loading up to 5.500 N/cm belt-width)

The fabric quality can be individually adjusted for higher demands.

Features:

- Endless and connectionless

- Customised manufacture

- No breaking points

- Homogeneous running behaviour

- Very high flexibility

- Low elongation

- Suitable for small roller diameter

- No thickening or adhesive points

- High heat resistance

Coating:

Application-based selection of the coating material. An innovative coating process, without the use of additional binding agent, guarantees a homogeneous and connectionless coating.

Coating: Rubber

- Hardness grade 40-90 Shore-A available

- Customised constructions possible

- High abrasion resistance

- Excellent grip properties

- Suitable for small roller diameter

- Temperature resistance 100 °C

- special rubber compound heat-resistant up to 170 °C (in peaks up to 190 °C)

- Homogenous coating

- No adhesive points → No breaking points

- High flexibility

- Resistant against most oils, greases and acids

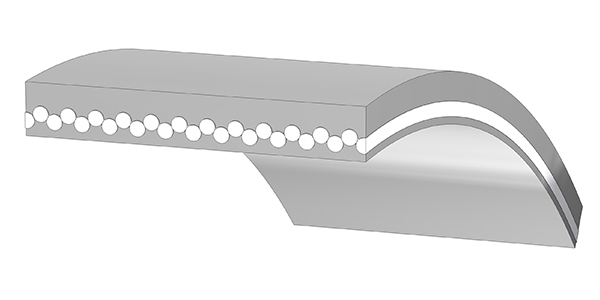

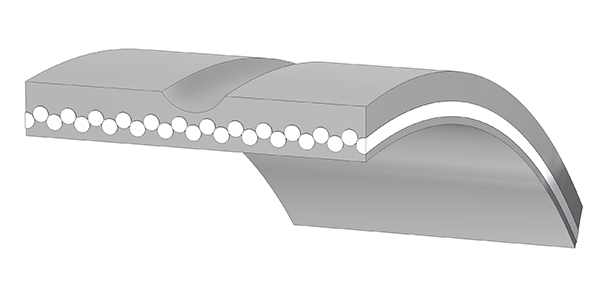

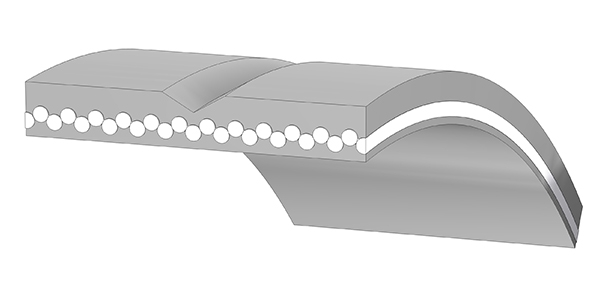

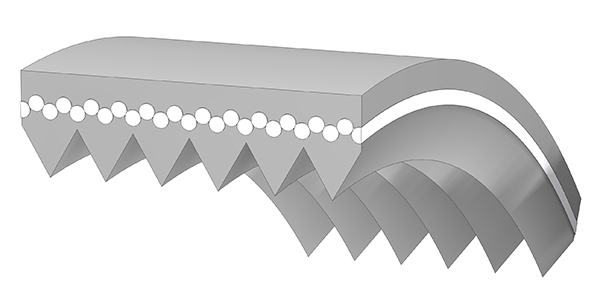

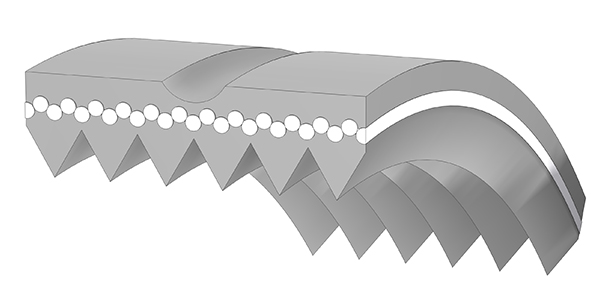

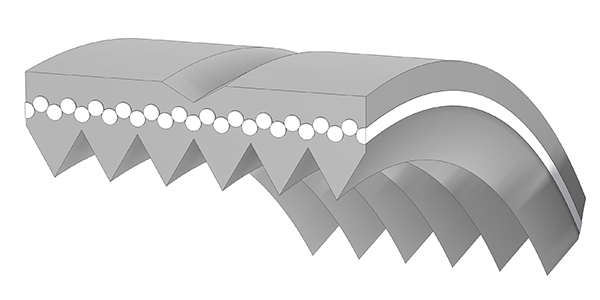

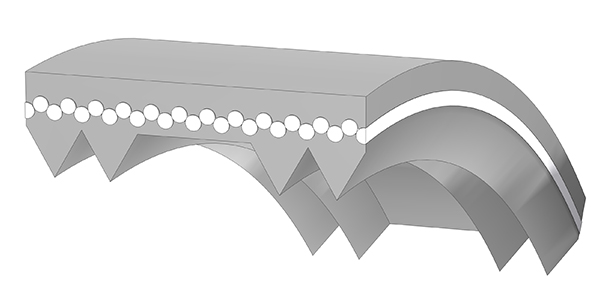

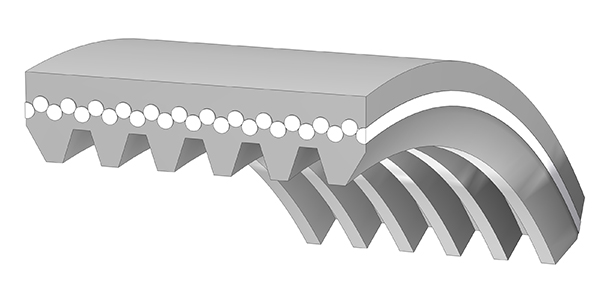

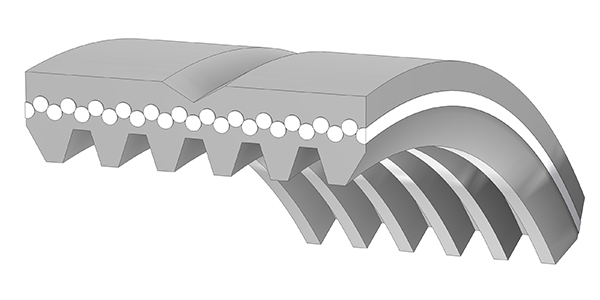

Profiling:

Customised milled areas and profiles on the pulley

and cable sides

Profiles: Pulley side

- Poly-V-Profil “J“, pitch 2.34

- Poly-V-Profil “L“, pitch 4.76

- Poly-V-Profil “M“, pitch 9.52

- V-5-V / V-7-V

- Taper gibs

- additional profiles on reques

Profiles: Cable side

- all half-round profiles on request

- V grooves: 90°, 140°, 160°

- additional profiles on request