Winding Belts

We have been developing and optimising winding belts since day one. In close cooperation with our customers, we design products of the highest quality. At this point, making the right choice is essential. Only the right winding belt guarantees smooth production processes. Trust in our many years of expertise.

Windingbelts are the central link between the machine and your end product, and they are an essential feature for quality and efficiency. Currently, our winding belts are mainly used in the production of paper and cardboard tubes.

Score of application:

Winding of paper and cardboard tube.

Fabric:

Customised selection of the type of fabric and quality. All fabrics are produced endless and connectionless with woven edges using a special production process.

Type of fabric: Polyester

Tear resistance: 2-3 mm belt thickness = 125 kg / cm belt width

Tear resistance: 4-5 mm belt thickness = 250 kg / cm belt width

Tear resistance: 8 < mm belt thickness = 375 kg / cm belt width

Type of fabric: Aramid (Kevlar©)

Tear resistance: Aramid = 500 kg / cm belt width

The fabric quality can be individually adjusted for higher demands.

Features:

- Endless and connectionless

- Woven edges (no fraying)

- Customised manufacture

- No breaking points

- Homogeneous running behaviour

- Very high flexibility

- Suitable for small roller diameter

- No thickening or adhesive points

- High heat resistance

- Non-directional

Coating:

Application-based selection of the coating material. An innovative coating process, without the use of additional binding agent, guarantees a homogeneous and connectionless coating.

Coating: PVC

- Hardness grade 35-90 Shore-A available

- Customised additional constructions

- Infinite combination options of various Shore hardness values

- High abrasion resistance

- Excellent grip properties

- Suitable for small roller diameter

- Temperature resistance -10°C / + 80°C

- Homogenous coating throughout

- No thickening or adhesive points → No breaking points

- Non-directional

- High flexibility

- Resistant against most adhesives, oils and greases

Calculation of a basic belt:

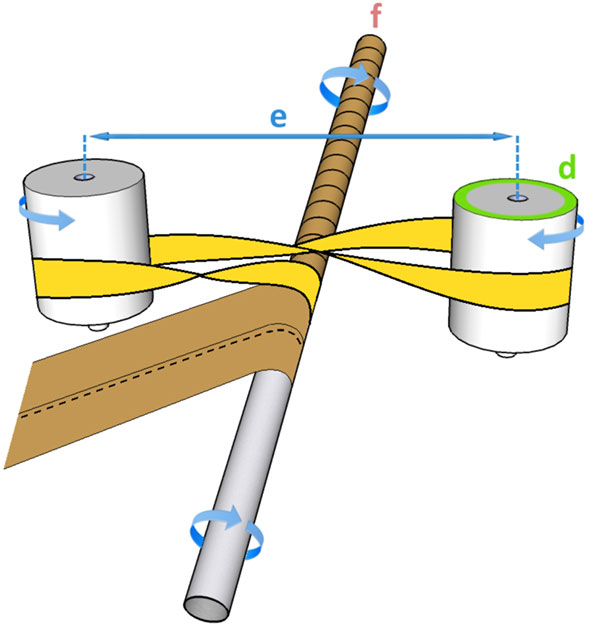

Calculation of the belt length: (2xe)+d+f

Calculation of the belt width: the belt should be 5-7 mm narrower than the final paper web

(Example.: final paper web 125 mm → belt width 120 mm).

| e | = | average distance between axles |

| d | = | circumference of the drum |

| f | = | circumference of the tube |